We all have systems – established either intentionally or by default. We use them to get ready in the morning, commute to work or school, accomplish our daily tasks, prepare meals and communicate with others. Even unstructured and chaotic ways of doing things are systems, although we may think of them as lack thereof. With good systems in place, individuals and organizations can accomplish things in ways that are efficient and effective.

The International Standards Organization (ISO) defines a management system as “the way in which an organization manages the interrelated parts of its business in order to achieve its objectives.” [1] ISO has released several management systems standards such as ISO 9001 and ISO 14001, the former providing guidance on quality management and the latter on environmental management.

With the release of the ISO 50001 standard in 2011, and a revised version in 2018, an Energy Management System (EnMS) specification for organizations was made available. Following our application series’ previously introduced format, three questions will guide our discussion, answering the what – to clarify terminology, the why – to understand the benefits, and the how – to put into action.

What is an EnMS?

- An EnMS – or Energy Management System – is a continuous improvement framework that establishes the way organizations need to set and achieve their objectives and energy targets to improve energy performance in an ongoing iterative process.

ISO 50001 “enables organizations to establish the systems and processes necessary to continually improve energy performance, including energy efficiency, energy use and energy consumption.” [2]

This management system is based on the Plan-Do-Check-Act (PDCA) continual improvement framework, also known as the Deeming Wheel, a four-step management methodology used to control and continuously improve processes and products. Figure 1 is a common depiction of this model, where the “Plan” step involves the establishment of objectives and processes that are carried out during the “Do” step, followed by the “Check” step where data and results are evaluated, and the “Act” or “Adjust” step aimed at improving the process before the next iteration.

To avoid any confusion, it should be noted that similar terminology is used to define products rather than processes. For instance, the term Energy Management and Information Systems (EMIS) refers to the “hardware and software products that comprise a broad family of tools and services to manage commercial building energy use.” [3] In our Fundamental Series on Building Analytics, two of these tools, Fault Detection and Diagnostics (FDD) and Energy Information Systems (EIS) are described in more detail, including a framework to help evaluate them. These supervisory platforms are designed to support operational systems such as those specified by the ISO 50001 standard, working in tandem to reap multiple benefits as we will see next.

Why Implement an EnMS with Analytics Software?

- Because an EnMS implementation supported by a robust analytics platform has proven benefits that include improved energy efficiency, risk management and financial performance.

- Because it also works as as a continuous improvement framework. An EnMS requires a continuous flow of data and continuous analysis of that data. Automated analytics enhances the use of information by prioritizing it to protect building occupants and the environment.

Even though ISO 50001 does not specify software applications as mandatory for the successful implementation of such standard, it refers to “complete monitoring and measurement systems connected to a software application capable of consolidating data and delivering automatic analysis.” [4] Given the requirements for a systematic and data-driven process, software applications such as building analytics platforms provide a continuous flow of sensor data, various data transformation functions to derive additional information from existing metrics, automated analysis and notifications, and visibility to conduct energy reviews, determine energy performance indicators and establish energy baselines.

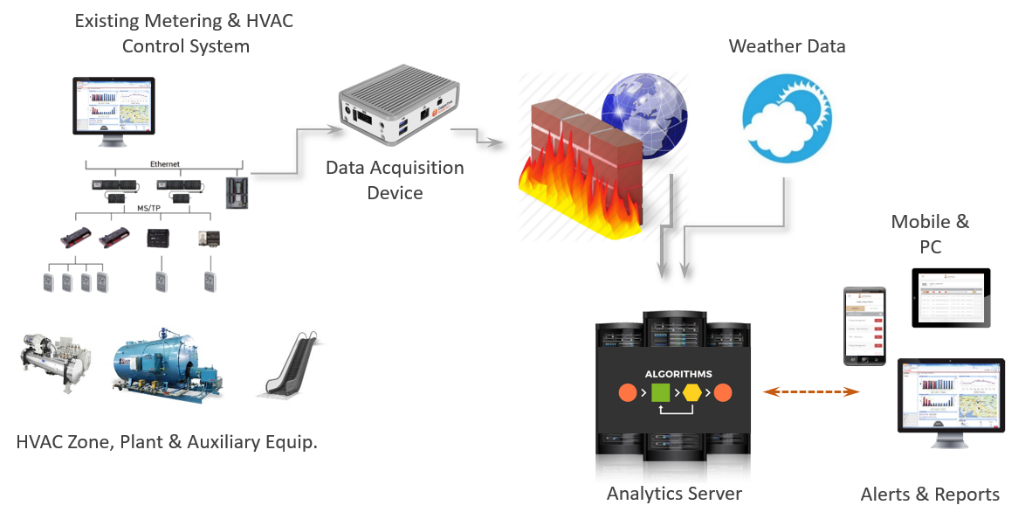

To help visualize how two processes can work in unison, the four-step management process – Plan-Do-Check-Act – shown as the inner cycle in Figure 2 is superimposed with the four-step data process – Acquire-Analyze-Advise-Act – shown as the outer cycle.

Figure 2. The Plan-Do-Check-Act management process and the Acquire-Analyze-Advise-Act data process working in unison.

During the planning step, the energy management team is assembled and energy policies are established. Data is acquired to help set objectives and targets, and to formulate action plans to deliver results. Followed by the doing step, action plans are implemented while data is analyzed. This makes valuable insights available during the checking step, where energy performance results are evaluated. Data is now valuable information used to advise the team of energy consumption anomalies and energy optimization opportunities. Next is the acting step, also known as the adjusting step, where further recommendations are acted upon to address issues and continually improve not only the facilities’ energy performance, but also the management process itself.

How to Leverage Software when Implementing an EnMS?

- Embrace your EnMS and choose the most suitable software – Upon deciding which management system best suits your organization, evaluate and select the software platform that would best support that framework.

- Integrate software functionality within the EnMS framework – Thoroughly understand your management system and use it to determine the required building data, energy resource metering and best way to organize and classify these data sets.

- Setup your software platform to meet EnMS requirements – Configure the required metrics, including performance indicators and energy baselines needed to evaluate the effectiveness of your action plans to accomplish the set objectives.

Embrace your EnMS and choose the most suitable software

Once an EnMS has been adopted, deciding which software platform is the most suitable for your organization involves examining its features and benefits in view of the EnMS’ requirements. It is important to align the energy data collection plan with the analytics platform’s data acquisition technology – as represented in Figure 3, validating that the required server/hardware, software drivers and protocols can collect the required data from Building Automation Systems (BAS), metering infrastructure or other data repositories.

Integrate software functionality within the EnMS framework

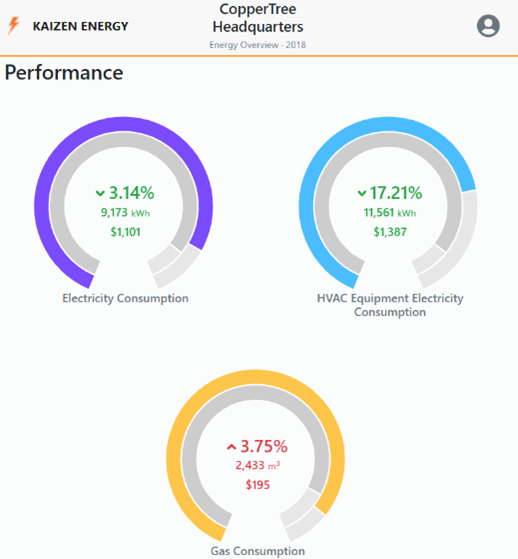

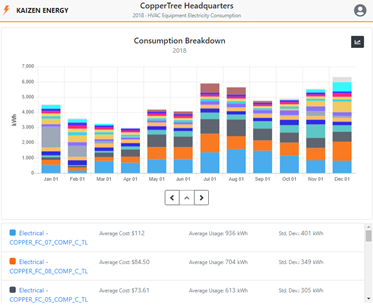

Given the software’s support role as a tool to help enhance the organization’s adopted energy management system, it is wise to integrate the software’s capabilities into the framework established by the EnMS. For example, organizations are required to develop and conduct energy reviews that include the analysis of energy consumption to help identify significant energy users and prioritize opportunities that would result in energy performance improvements. These requirements should guide how analytics platforms such as Kaizen Energy – CopperTree’s Energy Information System – are configured. Figure 4 below shows this tool’s ability to organize meters by resource type or equipment category. Figure 5 illustrates energy breakdown views to help identify significant energy users among the vast collection of systems, processes and equipment in any given building.

Set-up your software platform to meet EnMS requirements

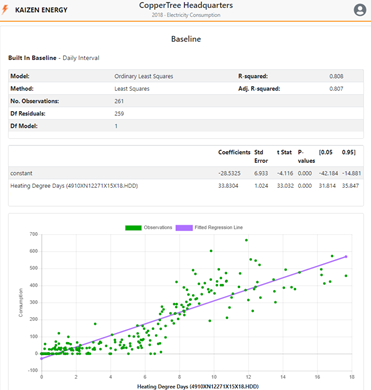

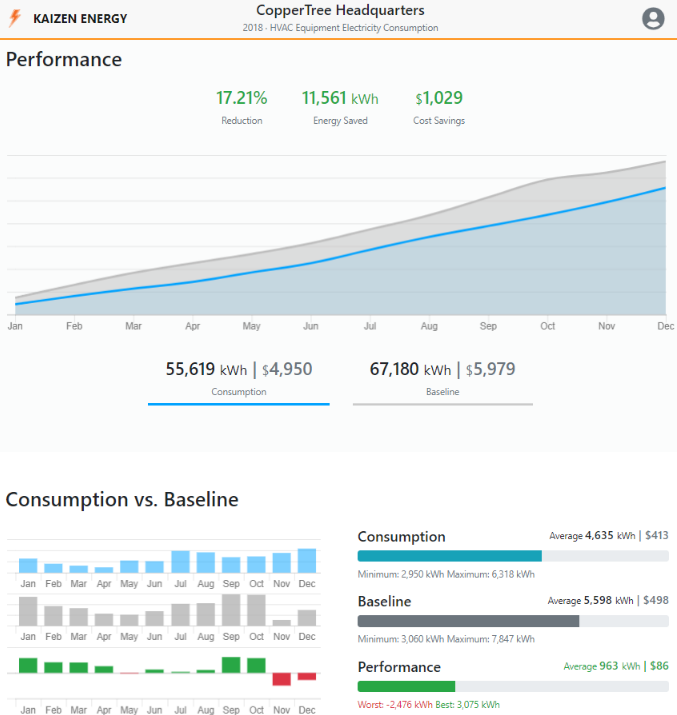

Energy Management Systems require organizations to determine performance indicators and establish baselines, two important tasks that are central to the overall goal of evaluating, and ultimately, improving energy performance. Kaizen Energy supports energy baselining through straightforward configurations to specify different independent variables including weather, occupancy, and process output. Figure 6 shows the energy baseline for a set of heating systems using linear regression with Heating-Degree Days as the independent variable to model energy consumption. Once a baseline is established, performance indicators such as those visualized in Figure 7 allow organizations to quickly determine if improvements in energy performance are indeed being realized.

Figure 6. Energy linear baseline Figure 7. Performance indicators

The potential for Kaizen Energy as a strategic tool to support operational decisions about energy use and consumption, and to continually improve energy performance is highlighted when the requirements for Energy Management Systems such as ISO 50001 are well-understood. Contact us to learn more.