Effective and energy efficient duct systems start with good design. It is critical to keep occupant comfort and health in mind from the outset to ensure proper indoor air quality in the long term, especially in office buildings, K-12 schools, and on university campuses where occupants spend so much of their time. Past good design, Commissioning Agents, Energy Managers, and Facility Managers can keep a few factors in mind in order to proactively mitigate issues and optimize energy consumption throughout their building portfolios.

Proactive maintenance for ductwork

To keep ductwork healthy and occupants comfortable, the easier and safer road to take is always going to be proactive maintenance. Dan Luzius, a Mechanical Design Engineer at DLR Group, suggests that “ducts should be periodically inspected every 6 months or annually depending on the building’s location and use”. Red flags for problematic ducts include uninsulated ducts in unconditioned spaces, disconnected, torn, or punctured ducts, blind-alley ducts, and inadequate return-side ductwork. Additionally, “look out for accumulations of soot or other dark material on the insulation where it covers loose duct joints. This dark area is a coating of dust which over time has accumulated on the surface as the air is being pulled through the insulation” (NREL).

“Look out for accumulations of soot or other dark material on the insulation where it covers loose duct joints. This dark area is a coating of dust which over time has accumulated on the surface as the air is being pulled through the insulation” (NREL).

Getting occupants involved for more sustainable operations

Ductwork not only needs to be maintained for occupant health, but also is critical to a building’s level of energy consumption, as “typical duct systems lose 25 to 40 percent of the heating or cooling energy put out by the central furnace, heat pump, or air conditioner” (NREL). Ductwork loses energy through conduction, air leakage, leaky return ducts, zone pressurization, and experiences energy losses when fans are turned off.

Outside of Facility Managers and Commissioning Agents inspecting ducts, increasing occupant awareness can make a big impact on day-to day energy savings. Some simple ways to involve building occupants is to educate them on the building’s objectives, and ask them to comply with smoking policies, clean up water spills promptly, water and maintain office plants, dispose of garbage properly, store food correctly, and notify the Facility Manager quickly if any IAQ problem arises. Another way occupants can contribute is to make sure that furniture and equipment do not impede the building’s “air circulation, temperature control, and pollutant removal functions of the HVAC system in mind” (EPA).

“Include energy dashboards so building occupants can see what their building is doing, enabling them to understand what’s going on and how their building is affecting them”

Getting occupants on the same page is as simple as making the building’s performance relevant to their daily lives. Luzius suggests that management should “include energy dashboards so building occupants can see what their building is doing, enabling them to understand what’s going on and how their building is affecting them” makes a big impact.

Using data to automate proactive maintenance

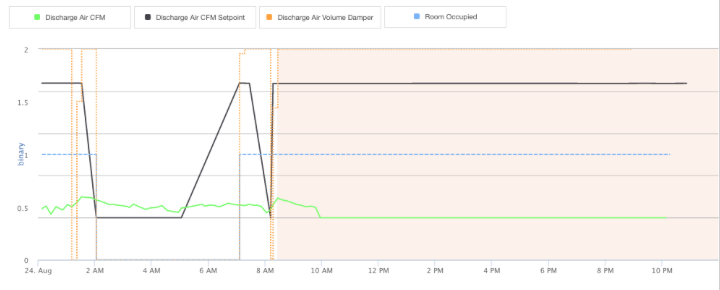

The data being generated from the BAS can also help point you in the right direction for where to prioritize duct inspection. Look for VAV’s that are not making the CFM Setpoint; this is a check that can be done year round, but will be most prominent during the Summer months when VAVs are operating at their maximum CFM setpoints. If there is a leak in the medium pressure duct, the issue should be distributed amongst multiple VAV’s tied to the duct. If a leak exists at the collar or flex duct from the medium duct to an individual VAV, only that one VAV should be effected.

The Green line is the airflow through the box which is registering effectively as 0 CFM. The Orange line is the Damper position which is pegged at 100%. Before sending a technician into the field to search for a leak, using the BAS remotely stroke the damper to fully closed and see if the air flow increases. If it does, the damper is operating in reverse, and the issue can be resolved remotely. If it does not, send a tech into the field to investigate in the following order after locating the VAV and confirming that the parnet AHU is operating.

- Verify the the Pitot tubes are connected the air flow sensor.

- Confirm that the actuator has not become loose on the damper shaft.

- Use the Damper override to stroke the damper fully open and verify that there is airflow. Using the override, close the damper and confirm that the airflow has been cut off. Use the VAV to confirm if it meets setpoint or not, you can also use a flow hood to measure the airflow if available.

- If airflow is not present check the collar connections to the medium pressure duct.

- If no leaks are present, look for other VAVs on the same run that are having trouble maintaining setpoint or are 100% open and go to the box closest to the primary duct run, and inspect the medium pressure duct between that VAV and one that appears to be operating properly.

If multiple VAV’s clustered together are having trouble meeting setpoint, skip to step 5 because the issue is not isolated to a single VAV.

Occupant health and comfort

Indoor air quality is vital to occupant health and comfort, and duct systems play a key role in maintaining indoor air quality. Improperly pressurized ducts can suck flue gases from furnaces (which is particularly concerning with carbon monoxide gas), and radon gases can enter a building from surrounding soils, (exposure to radon is the second leading cause of lung cancer). In lab spaces, there are even more concerns around hazardous gases and chemicals. Because occupants spend so much of their time indoors at work or in the classroom, it is of utmost importance to their health that they work in safe environments, breathing clean air.